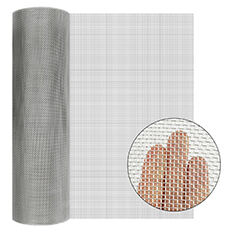

The launch of the metal mesh screen by Xuancheng aroused strong interest in many industries. The 80 mesh screen filter is an amazing tool that purifies liquids in ways we never could. In this article, we will discuss how the 80 mesh screen filter operates, its significance, and how it is useful for different companies that can enhance their products and services.

First of all, if you are looking for a filter that does a great cleaning job on the liquids, 80 mesh screen filter is the best for you. Specially-designed screen that traps any small particles or impurities found in end liquids. This implies that the filtering is way more expert, and the output that’s released is of far superior quality.

As an example, in food and beverage, with juices and wines, many companies use wire mesh screens for cleaning. Using these filters not only enhances the taste of the drinks but also ensure that it is safe for human consumption. The filter helps keep germs and other harmful things that can make you sick away from everyone by taking away the things that are not wanted.

Another screen filter at 80 mesh is also very useful when it comes to filtering liquids in a more gentle and sophisticated way. Its precise screen technology enables the filtration of fluids at a higher level than traditional filters. This matters in contexts where we need to be especially mindful about what is mixed into any of the liquids.

For example, the medicine-making industry uses 80 mesh screen filter to clean liquids to remove harmful like bacteria and viruses. This is incredibly important because in the synthesis of medicines and making of vaccines, we need them to be very pure and free of all impurities that could potentially cause disease. The filter helps make sure the medicines are safe for humans to run.

One more wonderful aspect of the 80 mesh screen filter is that it is capable of processing a huge amount of liquid at once. This great capacity is also one of the reasons why a high-capacity storage tank can be found in various industries as it is able to endure high production requirements in case of large-scale manufacturing. It is capable of cleaning vast amounts of liquid without any dissipating or degrading quality.

In the cosmetics field for instance, a screen filter sized at 80 mesh is utilized for cleaning beauty and skin care products. These filters can eliminate small particles that can irritate the skin or trigger allergic reactions. This results in safer and more effective products for consumers, so that no one has to give up on the benefits that cosmetics can deliver.

Customized services consist of the selection of filter material dimensions, pore size and shape and other aspects. They can also provide custom-designed filters based on customer demands and specifications of the extruder. Customized services enable the optimization of filter parameters like structure materials, filtration precision and other parameters. This will increase the filter's filtration efficiency and lifespan. The manufacturing process is based on the requirements of the client, and waste is avoided to lower costs. Choose the materials with most suitable properties for the requirements and situations of the client in consideration of the needs for heat resistance, corrosion resistance, wear resistance and so on. Choose a filtering structure that will be suitable for the installation and usage requirements of your client.

Yangzhou Xuancheng Filter Screen Co., Ltd. is a reputable manufacturer of extruder filter, which has been dedicated for many years to the creation and development of extrusion-based plastic filters and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other products, as well as the filtering of chemical fiber spinning and other industries. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt, wire mesh mist eliminator, etc. With a wide assortment to meet the demands of various clients. The company has offered services to more than 500 famous plastic, petrochemical and metallurgical production companies across the globe, and has a broad market coverage and strong impact on brand image. The company has a strong technological force, high degree of specialization, complete production equipment and an extensive testing process. The company has been accredited with ISO9001:2015 to ensure the stability and reliability of its product.

The company has a knowledgeable after-sales service team, through telephone, online customer service along with social media and other ways of communication, it is able to quickly provide customers with technical support, product consulting and tracking cargo and troubleshooting, among other services. The company will contact customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the data. Furthermore, feedback is also fed back to product design and production departments to enhance the quality of products and services. The experienced team analyzes the root cause of the problem and provides basic solutions to minimize the chance of repeating the same problem. When the two are in harmony, will we be able to provide customers with an exceptional after-sales customer experience. This strengthens customer loyalty and promotes the long-term development of the enterprise.

The filter of the extruder is made from high-quality steel and features small pores for filtering. This helps to eliminate impurities, and increase the purity and quality of the polymer. The filter's structure is designed to ensure constant filtration efficiency while the material flows through it, which reduces the likelihood of clogging. This helps to ensure that the production process is continuous. Metal filters have a high resistance to wear, corrosion and high temperatures. Filter products can be customized to meet the requirements of various customers and to be compatible with the equipment. Filtration efficiency that is efficient reduces the time it takes to repair due to blockage of impurities, and also increases the productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy