Selecting the appropriate type of mesh is thus critical when we mention filtering things. Mesh is a specialized material that aids in the purification of liquids by capturing dirt and other impurities. Xuancheng 100 micron filter mesh with strong and solid can easily handle heavy-duty filtering. So, what makes a 60 micron filter mesh, and why is it great for your work? Let’s explore this together!

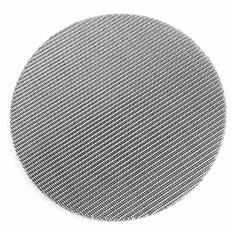

A mesh filter is a type of filter mesh that has small hole in it like net. As liquids flow through the mesh, the small holes trap dirt, sand and other impurities. These holes are measured in microns. A micron is an extremely small unit of measurement. The smaller the holes, the smaller the particles it can catch. That means, a net with smaller openings, such as a 60 micron filter mesh, can catch smaller dirt particles than what the net with larger openings can.

The 50 micron filter mesh used is one of the best features that would help you to also get a good filtering because there are some meshes that don't do as filtering as they should. Bigger means it also collects more dust and debris. The more particles your filtering system picks up, the better and faster it can work. This is a good thing because you're able to clean more liquids in a shorter period of time, meaning less waste.

Thin mesh, like a 60 micron filter mesh, is particularly effective at snaring sand, silt and other fine particulate matter. These small particles can block pipes and machines, which can lead to major troubles. With a filter mesh size of 60 micron, it can prevent these particle from damaging your equipment. So you save time and money later on repairs, which is what everyone wants!

Due to multiple reasons, selecting 60 micron filter mesh is a wise option for your filtration needs. First, it provides reliable performance that you can depend on. With a strong and high-quality mesh from Xuancheng, you know your filtering system will do its job, always. It is important because you will not have to worry about your equipment breaking down or not doing its job.

This is particularly critical in industries such as pharmaceuticals or food processing. In such environments, even small levels of impurities can cause major issues. With a proper 60 micron filter mesh, not only will your fill products have to meet stringent quality standards, but they will also be highly beneficial for your customers. This keeps customers safe and happy, which is what every business ever wants.

A combination filter mesh with a 60 micron density is best for heavy-duty requirements. Well, this device is quite powerful, and it is designed to be rugged so it can handle the tough jobs and not get killed easily. Whether exposed to corrosive substances, under pressure, or demanded to do intensive filtering – purchased from Xuancheng a high-quality inch 60 micron filter mesh will do the job.

The company has a professional after-sales team, utilizing the phone, customer service online or social media, as well as other contact methods, can efficiently provide customers with technical support, consultation on products along with cargo tracking, troubleshooting and other comprehensive services. The company will contact customers on a regular basis after they have purchased to learn about their current usage of filters and their future plans. The after-sales department can handle customer complaints and feedback promptly by capturing the data. Furthermore, feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The expert team analyzes the cause of the issue and offers solutions that will decrease the chance of it repeating. Only when both work together can we offer customers an exceptional after-sales customer experience, which in turn strengthens customer loyalty and promotes the long-term growth of the company.

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

The customized service includes the choice of filter pore size materials, shapes, and other factors as well as the ability to create custom filters that meet the specific requirements of each customer and the specifications of the extruder. By utilizing customized services, the structure and material, the filtration accuracy and other aspects of the filter can be optimized so as to enhance its filtration efficiency and service life. The process is designed according to the specific requirements of the customers, while avoiding unnecessary waste in order to save customers money. Based on the particular requirements and requirements of the customers, considering the special demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Select materials with the same properties, for example stainless steel, galvanized iron and more. Create a filter design that is appropriate for the installation and usage conditions of your client.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy