There a lot of advantages of ss wire mesh that make them very useful in multiple applications. A major reason that individuals utilize wire mesh discs is that they are seriously sturdy. These disks are made of high quality material so they can handle a significant amount of pressure and will not break for a long time. That sturdiness is critical, as it means they can be reused many times without requiring frequent replacement.

Wire mesh discs also provide you with the great benefit of uniformity and consistency. That every wire mesh disc is produced in the same way which means they perform equally every time. In fields where precision matters, this is crucial. E.g. taking precautions in food production is mandatory as we want to keep everything clean and safe. Wire mesh discs can be easily cleaned and maintained, which helps to minimize contamination in sensitive areas such as food and beverage manufacturing plants.

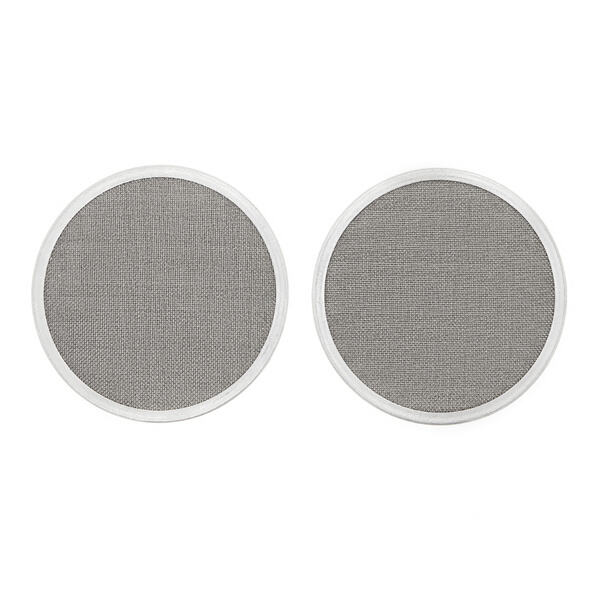

There are many applications for stainless steel wire mesh such as filtering, spacing and perforating materials. Wire mesh discs are used primarily for filtration. Filtration is a very important process as it helps to keep liquids or gases clean. These also have tiny holes (or pores) in them, making them resemble wire mesh discs, and filter these substances according to their size. That means they trap all particles they do not want to see come through and allow the cleanest liquid or gas to pass.

Wire Mesh Discs: Each disc is made with intricate techniques to make sure that the process is done correctly. This is done primarily with specialized equipment, like presses and dies. These tools are used to mould the wire mesh material into the right shape and size. That way every disc's the right size with the right holes.

Processes like welding, weaving, and soldering are also used to make a product. Different techniques have been used to weld or bind the wire strands together, forming a solid and homogenous product. And the use of these techniques could help produce the discs that are made of durable wire mesh and functional in application.

Finely Mesh vs Coarsely Mesh — First things first, you need to think about the mesh size. Mesh size refers to the number of wires in one inch. That helps to determine how large the holes in the disc will be. If the holes are oversized or undersized for your specific needs, the disc won’t perform to its full potential.

In addition, wire mesh discs are adaptable tools that may be utilised in a variety of settings. Their versatility makes them an intelligent investment for businesses looking to improve. Additionally, they can also be tailored to meet individual needs and requirements, making them an even more valuable option for manufacturers to create wire mesh discs.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters which has been dedicated for many years to the development and production of plastic extrusion filters, and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of sheets, films and other industrial processes, as well as the filtration of chemical fiber spinning and other industries. They comprise filter mesh, edging mesh spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor mesh belt wire mesh mist eliminator and so on., with a complete collection to meet the needs of different customers. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great brand influence. The company is equipped with strong technical strength and has the most advanced production equipment, as well in a complete test method. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

Customized services consist of the selection of filter material dimensions, pore size and shape and other aspects. They can also provide custom-designed filters based on customer demands and specifications of the extruder. Customized services enable the optimization of filter parameters like structure materials, filtration precision and other parameters. This will increase the filter's filtration efficiency and lifespan. The manufacturing process is based on the requirements of the client, and waste is avoided to lower costs. Choose the materials with most suitable properties for the requirements and situations of the client in consideration of the needs for heat resistance, corrosion resistance, wear resistance and so on. Choose a filtering structure that will be suitable for the installation and usage requirements of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy