Steel filter mesh for liquids and air cleaning made by Xuancheng As a business, this mesh is fantastic for you as it has a long life and is an effective option when used to filter harmful substances. When you choose Xuancheng for your Xuancheng steel filter mesh PRODUCT, companies can be assured they are getting a superior quality product.

The steel filter mesh is very useful for cleaning dust and other harmful substances in the air of factories, industrial parks. The cleaning also helps ensure the air is safe for workers to work in. Breathing clean air helps everyone stay healthy and reduces the health risks caused by breathing problems associated with unhealthy pollutants. If the air quality in your office building is high, this ensures that workers can do their jobs more effectively and are less likely to get sick while working.

Steel filter mesh is great since it can be used to clean both liquids and gases, which is quite good. This Xuancheng Wire Mesh Cloth tool is universally beneficial for a vast number of businesses as it can be used in various ways. It can assist, for example, in food and beverage production, oil and gas extraction, or chemical manufacturing. Clean liquids and gases are a critical need for safety and quality in these areas. The following text is introduced in Aluminum Mesh Supplier This type of steel filter mesh in Xuancheng can well solve all kinds of needs.

It has been specially treated to combat rust and corrosion so that you can trust buying a steel filter mesh in Xuancheng even more. The result has been that the mesh is used in businesses for over 10 years without failure or without break and replace. Because of this durability, businesses do save some cash in the long run. Investing in security lights is an excellent way for them to minimize these additional costs and keep their minds free of other worries so they can focus only on the things that matter most.

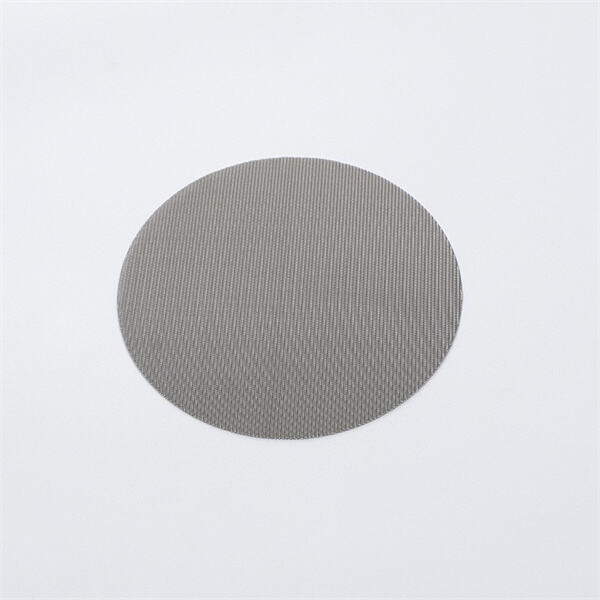

The company uses a weaving pattern to join together the steel mesh which ensures that it is both sturdy in construction and high in cleaning performance. Each filter is meticulously crafted. This level of manufacturing care ensures the Xuancheng Sintered Filter Mesh works effectively every time it is deployed. Focusing on quality allows Xuancheng to ensure that its customers are provided with a customized product that meets their requirements and high performance.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy