Wire mesh is a sturdy, easily tweakable material, with commercial and residential applications. The material used is stainless steel, a tough and rust resistant material. This makes the Xuancheng metal mesh ideal for applications in industrial settings where strength and service life is critically paramount.

SS wire mesh is a material comprising many small interwoven wires forming a mesh. This structure yields a strong flexible material that can be applied in various forms.

SS wire mesh is advantageous in that it is a long lasting material. Stainless steel is a good strong material that will not rust or burn out. This is what makes SS wire mesh ideal for working in tough environments, where some other materials may not withstand the same. The SS wire mesh are also highly flexible and customizable to fit various shapes and sizes. This makes it an excellent option for projects that must have a certain design or size.

There are several advantages to using the SS wire mesh in the industries. Its durability and strength are some of the key advantages. SS wire mesh is strong and can bear heavy loads and can also resist high temperature which makes it excellent for manufacturing and construction building projects. Xuancheng stainless steel mesh is resistant to corrosion, so it can last for a long time without needing to be replaced. SS wire mesh is simple to clean and upkeep; it is a popular choice and a great economical solution for many businesses.

When you are selecting SS wire mesh for your application, there are some factors to consider. First you'll want to consider the size and shape of the type of mesh you need. SS wire mesh is offered in all sorts of sizes and patterns, so be sure you select one that you’ll have the ability to utilize for your undertaking. You also have to account for the wire thickness and the grade of the stainless steel. Thicker wires are less likely to break, but they can also be pricier. Last, consider whether you have any special needs, such as heat resistance or resistance to chemicals.

Applications of SS Wire Mesh SS Wire Mesh finds frequent applications in different sectors and industries. In construction, it is a type of cementitious material that is used as a reinforcing material for the concrete and as a material for the making of a strong, tough building. In farming, it is employed in the construction of fences, cages and screens to safeguard crops and animals. In manufacturing, it acts as a filter in liquids, and as a filtering agent for separation of household and industrial chemicals. Versatility of Xuancheng stainless welded wire mesh is good for a variety of reasons, and it can be used for a lot of things in many different fields of industry, making it an extremely useful resource for countless businesses in the world.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The company has a knowledgeable after-sales team, utilizing phone, online customer service, social media and other methods of contact, they can offer customers quick technical assistance, product advice as well as cargo tracking as well as troubleshooting services. After the items are purchased, regular communication with the buyer is carried out to understand the usage of their filters as well as the future requirements and expectations. By collecting customer feedback and issues encountered in the service after sales department, it is able to respond promptly and provide prompt treatment or respond. Additionally the information is relayed back to the design or production team to aid in the constant improvement of products and services. The expert team analyzes the root cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. When the two are in harmony, can we provide customers with an excellent after-sales service experience, which in turn enhances customer loyalty and aids in the development of the enterprise.

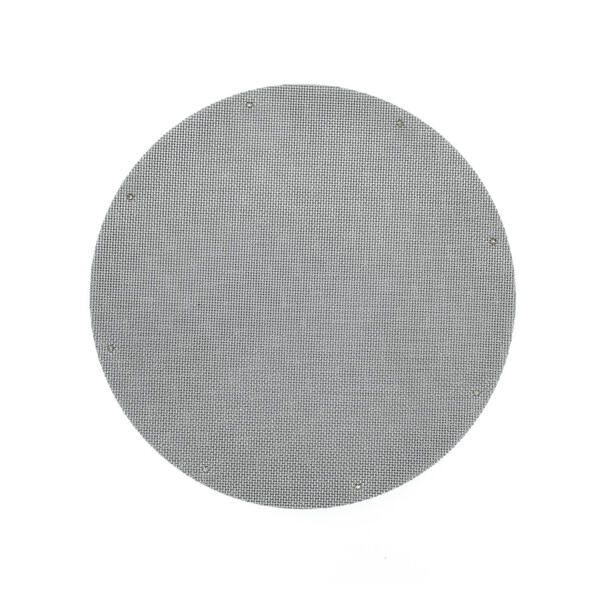

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Customized services involve the selection of filter material, pore size and shape in addition to other aspects. They can also provide personalized filters to meet customer specifications and requirements for extruders. With the help of customized services, structure, material, filtration accuracy and other parameters of the filter can be improved in order to increase its efficiency at filtration and prolong its service life. The process is designed according to the specific requirements of the customer, and avoids unnecessary waste, so as to save customers money. Choose the materials with most suitable properties for the requirements and needs of the client, taking into account the needs for heat resistance, corrosion resistance, wear resistance etc. Choose a filtering structure that is appropriate for the location and usage conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy