Filtration — It is a process for the separation of solid particles from a liquid or gas, and removal of impurities. This process is a hell important one, if we do not filter it well then these bad creatures can take our home and spread inside our body or machine. As a result, these can cause serious health hazards or even destroy our machines. For this reason it is critically important that we use the correct filter to protect our health and maintain the proper operating conditions of our equipment. A popular filter among many people is the .

It is a unique type of material that is created by closely knitting yarns. When woven together, these make for a kind of mesh with lots of little holes. These small holes in tea back permit the passage of liquids and gases, but block other particles including leaves or other part jsonly liquid will pass through it. Each opening is called a mesh size and can range from hundreds to thousands of mesh sizes. This means/ensure about micron mesh filter is adjustable for small particle as well large to capture.

The stainless steel wire mesh filter works as one block which means it can process into the almost any shape and size usages in different tasks and sectors. Some sectors include — Food and Beverage, Pharmaceuticals, Automotive & Environmental Cleaning. Every job is different and each one has its own particular requirements for filtering on the base of kind of particles that have to be removed, temperature of liquids and much more. Xuancheng is a company that produces special mesh filter fabric which can be customized or modified to suit the particular needs of each job,

Mesh filter fabric is also used in the food and beverage industry, where it sieves out solid particles of impurities from liquids: juice, wine, beer. The size of the hole in the fabric is critical. When they are too small, the mesh can easily clog, and when it is too big the unneeded particles will get across. For safety reasons, Xuancheng developed the FDA approved mesh filter fabric which is produced that follows strict food grade safety standards. High Temp & chemical resistant; This fabric will also withstand high temperatures and most chemicals.

Mesh filter fabric is used for cleaning air, fuel and oil that enters the engine system of automotive industry. Most importantly, it protects the engine by preventing dirt and debris from entering. Fabric that is resistant to these forces, like heat pressure must be strong. Xuancheng supplies wire mesh filter cloth of stainless steel, carbon steel, copper & brass. This material is customizable so that it can be make in various sizes and shapes to best suit the needs of each vehicle.

Take Xuancheng as an example, mesh filter fabric is always made from synthetic materials like polyester, nylon or polypropylene. They are strong and stretchy, and they resist chemical agents and ultraviolet radiation. Yarn is weaved or knitted by using the best in class machines that provide uniform and robust meshes with low levels of defects or variations. Xuancheng also has a strong quality control system which monitors every batch of mesh filter fabric for compliance with all set specifications.

Mesh Filter Fabric vs Other Filters — (Paper, Sand) Other filters: go to 02.07 of this video Where mesh fabric shine is that it has a competitive sterile surface-to-area ratio compared to Paper or sand filters. One, it has better dirt retention — offers larger amount of incurs before change or cleaned. Which means less work on the part of the user, fewer filter changes, lower maintenance costs and in general less waste. Second, mesh filter fabric has low pressure drop thus it helps liquids and gases to flow seamlessly without clogging. This creates huge savings in electrical energy and guarantees constant output quality. Thirdly, mesh filter fabric has a greater lifespan than the disposable filters which is also better for the planet and more sustainable.

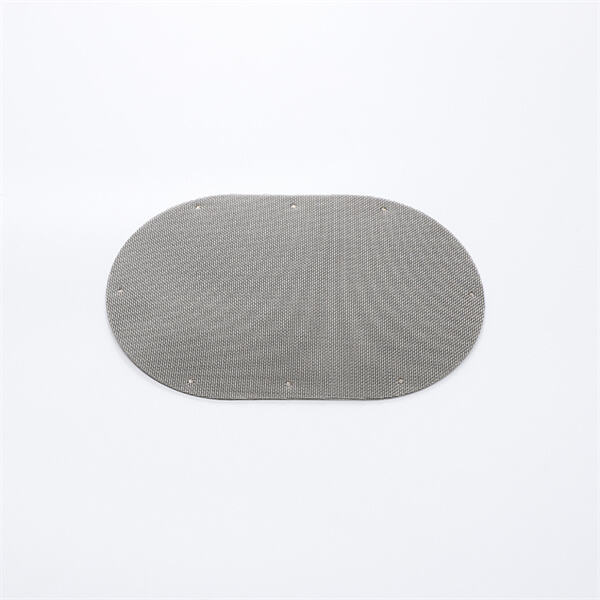

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

Customized services include the selection of the filter material, pore size and shape, as well as other aspects. They can also provide customized filters according to customer requirements and specifications for the extruder. The customized services allow the optimization of parameters for filtering such as structure material, filtration accuracy and more. This can improve the efficiency of filter filtration and longevity. The production is performed according to the specific requirements of the customer, and avoids excessive waste, in order to save customers money. According to the specific needs and applications of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Choose the materials that have corresponding properties, such as galvanized iron, stainless steel, etc. Create a filter design that is appropriate for the installation and operating conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy