Filters are integral to our daily lives. They keep us from poisons, help deliver clean drinking water and fresh air. Otherwise many of the things we use on a daily basis could be dangerous. Filter screen packs are a critical component in the way filters operate. These packs are utilized to isolate and dispose of soil and other mass from fluids as well gases. Filter screen packs from Xuancheng are ideal for a broad range of applications in the filtration and separation industry, through which liquids or gases including water can be purified easily.

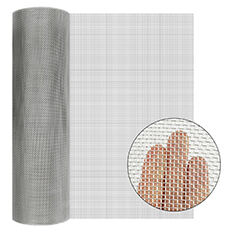

A stainless filter screen consists of multiple layers of mesh material. Each layer contains a family of holes in varying sizes. It is crucial as it helps in trapping varieties of liquid or gas particles such as dirt and this serves the purpose. As liquid or gas pass through those mesh layers the dirt and particles get stuck on it, leaving only one side clean with the expected quality of liquid or gas. This implies that the various holes scalps of several different dimensions can work together to catch maximum number three particles at the time dawning liquid or gas, subsequently making it culminate absolutely pure.

Xuancheng In case of filter screen packs, special mesh technology is used by them to make it work better than ever. This mesh is woven in very fine and tight sections, using only the strongest materials to ensure an efficient filtering runtime every time. Thus, the mesh effectively works in removing dirt and particles. It is engineered not to clog up, which cannot be overemphasised because this ensures the filters can function at optimal levels even under adverse situations. The mesh can withstand high temperatures and pressure, allowing it to be used in a wide range of situations.

It does not just protect us though, filter screen packs also help to safeguard our machines and equipment throughout the whole process. When filter screen packs are put into the machines for example pumps, valves and pipes — it helps in avoiding getting them clogged or damaged by dirt & particles. That is extremely valuable since it saves cash with maintenance and repairs. Machines last longer and will run more effectively when you take the time to protect them. Therefore, filter screen packs are as helpful for protecting humankind and the machines that work.

Filtration of Different TypesXuancheng provides a variety of filters for various applications. The filter screen packs of theirs can be applied in many fields, including the medicine industry, food and drink industry as wellas sewage treatment factories etc. This means that, regardless of your filtration needs there is probably a filter screen pack out there to assist. Xuancheng also creates special configuration and custom-make how they would like pack filters. If you have a special condition, they can build it in the way you need.

One of the great advantages that filter screen packs have is they are simple to install and clean. Here, Xuancheng offers easy maintenance and clear-cut instruction on how to install the filter screen packs. You only need to remove the filter screen pack, clean it and put it back in place. It is quite an easy process, as well as making sure your filter keeps lasting and being reliable. If you want the filters to work efficiently and effectively, then regular maintenance is very important.

The filter in the extruder is made of premium metal with very fine pores. This helps to eliminate contaminants and enhance the quality and purity of the polymer. The structure of the filter is designed to ensure a high efficiency in filtration while the material is flowing through it, thus reducing the possibility of the likelihood of clogging. This increases the efficiency of production. The metal filter is highly resistant to resistance to corrosion, wear and high temperatures. Customized filter products are available to satisfy the requirements of different clients, and also to fit with the equipment. A high-performance filtration system decreases the time lost to interruptions caused by the accumulation of impurities and boosts the productivity.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy