Black Steel Mesh is commonly used in a wide range of applications and has high tensile strength. It is composed of a high-strength steel that makes it tough, durable, and resistant to breakage. There is a mesh of black stainless steel used in different places like construction, designing buildings, safety and other things like crushed stone. There is a well-known brand in the production of black steel mesh Xuancheng. Here we explore the interesting things and capabilities of black steel mesh

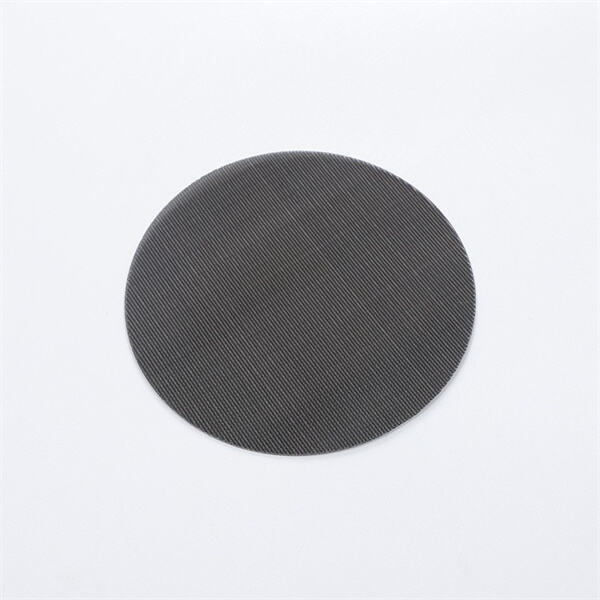

Most importantly, black steel mesh has considerable strength. It is constructed of very rigid steel. This resilient material can support heavy loads and will rarely tear or rip. Because of this, black steel mesh is commonly used in construction to reinforce concrete structures even more. For example, when workers are building a bridge or a tall building they will add black steel mesh to the concrete mix. This Xuancheng Sintered Filter Mesh addition will ensure that the structure is safe and durable. This also keeps the building from falling during a heavy storm or tremor which can be harmful.

In many construction projects, black steel mesh is very helpful. You can commonly find it in a number of building components such as floors, walls and roofs It helps in making the entire building solid and secure shape when installed. In addition, black steel mesh could act as water brushes while being changed to prevent temperature fluctuations that could cause the building to become ill. Black steel Xuancheng Wire Mesh Cloth is a very nice piece that has proven to be practical in architecture and design. And other example of this is when it can be modeled into fancy shapes and complex patterns in a way that would look all nice and sexy at the facade.

Other than construction, black steel mesh plays a huge role in providing safety as well. They can be found In fences and gates to prevents people from entering dangerous locations. The example can be able to use at around a school and park keep awaying children from dangerous places. But for more superficial protection against burglary, there are black steel mesh used both in windows and main house entries! Since the Xuancheng Filter Element is so strong that can not easily be cut through or pushed out, it helps in keeping people safe and secure.

Modern building designs are incorporating black steel mesh in a big way. It is used by architects, builders to design attractive and stylish buildings. For this purpose, they can take advantage of black steel mesh to make various textures and patterns on the exterior and interior of buildings. This can provide a contemporary or industrial look to a building, which is in high demand today. Usually, black steel mesh is used in museums, galleries or public buildings. These are types of structures that need something that is strong, as well as looks good; black steel mesh happens to take care of this.

In this article, we will discuss the 5 solid reasons to select black steel mesh and give up any other material. One of the best things about it, in the first place, is that its durability and resilience can brave any kind of weather or weight without any hassle. Because of its toughness, black steel mesh is suitable for many types of building projects On top of that, concrete is one of the cheapest building materials out there–great for those budget friendly builders. Black steel mesh is also quite easy to install, and it requires minimal upkeep. So even after installation, it can go on for many year without any repairs or additional care.

Customized services consist of the selection of filter material dimensions, pore size and shape and other aspects. They can also provide custom-designed filters based on customer demands and specifications of the extruder. Customized services enable the optimization of filter parameters like structure materials, filtration precision and other parameters. This will increase the filter's filtration efficiency and lifespan. The manufacturing process is based on the requirements of the client, and waste is avoided to lower costs. Choose the materials with most suitable properties for the requirements and situations of the client in consideration of the needs for heat resistance, corrosion resistance, wear resistance and so on. Choose a filtering structure that will be suitable for the installation and usage requirements of your client.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy