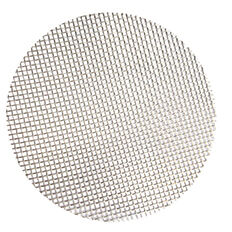

✘Stainless steel is a robust, non-rusting metal("") Due to this usefulness, you can apply it in a lot of scenarios. Different meshes – this strong material 316 stainless steel wire mesh. This wire cloth is employed by regular everyday individuals at their jobs and industries — this would be impossible if not for the tedious process of weaving stainless steel wires into a mesh that can fit practically any function.

This 304 stainless steel wire cloth has many USES. Screening of material to size is the other major use for the screen in both solid and liquid applications. This means that it is further divisible into other substances which will make it more usable. In laboratories, for example, it can be used to clean impurities from a liquid. This can also be utilised as a protectiveshielding never to prevent the destruction of some objects in both factories or industrial set ups. It also has the ability to provide a very polished finish that makes it useful for decorative use, in many creations or popular areas.

Wire Cloth Made With 304 and 316 Stainless Steel Types Although due to their resistance both are tough, they have differences you need to know about. 304 stainless steel is probably the most common, and least expensive type of any silverware.Whether it's in stores or online. Which makes it a favorite choice for so many projects. 316 stainless steel, however, is further resistant to rust and is used where such strength must last an incredibly long time. This is especially critical in areas such as saltwater or an environment high in acids where corrosion resistance can be essential.

In general, the chemical composition of stainless steel screen wire is very similar to that specified in DIN X5CrNi18-10 and matches that.Its strength and hardening allow it highly durable for filter processing therefore, below are some uses with sieves or for filtration. 【Go ahead】 This good is jet will have a long life and it ensures that, no fault happen in the cancellation. It will be a card that holds quite a bit of pressure in it too, but with the rugged design setup they have going for it you can rest assured knowing this thing is not just about to snap or get busted up quickly. The well-deserved reputation for Mcquiry is also due in large part to the fact that it does not have a tendency to bag out when water flows through it, and will filter effectively for many seasons of service with minimal enjoyment as an outcome. 304 stainless steel Wirecloth is to confirmed that all filtered or sieved material are working under the appropriate and safe condition.

How to Cleaning and Maintenance of 304 Stainless Steel Wire ClothContrary to what many people will tell you, cleaning your metal mesh screen is far more simple than it seems prostituïda sant feliu de guixols es sheepflor.

Regular Cleaning Required When it comes to 304 stainless steel wire cloth, you need to clean them in a proper way so that their well performance will be maintain. Note: You should never apply strong chemicals or abrasive material while cleaning wire cloth as they can harm the mesh. Instead, opt for some mild soap and warm water. The wire cloth is carefully but unsubtle dusted similarly. From there, rinse well with clean water to remove soap residue and then dry it before using on the next occasion. This piece of wire fabric Upkeep Method For the reason that regularity enables the cable fabric to maintain effectiveness more than a duration of many years.

The customized service includes the choice of filter pore size materials, shapes, and other factors as well as the ability to create custom filters that meet the specific requirements of each customer and the specifications of the extruder. By utilizing customized services, the structure and material, the filtration accuracy and other aspects of the filter can be optimized so as to enhance its filtration efficiency and service life. The process is designed according to the specific requirements of the customers, while avoiding unnecessary waste in order to save customers money. Based on the particular requirements and requirements of the customers, considering the special demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Select materials with the same properties, for example stainless steel, galvanized iron and more. Create a filter design that is appropriate for the installation and usage conditions of your client.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy