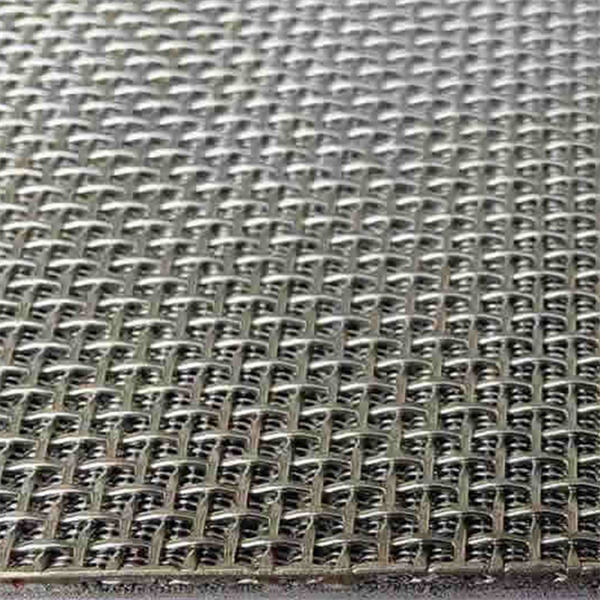

Sintered Wire Mesh Sintered wire mesh is a base metal woven mesh that has been sintered with each other in high temperature to create a new type of structured porous material. This method results in a resilient, robust material with exacting filtration characteristics. The most cost-effective and practical way to filter out impurities from both liquids and gases is with the use of Sintered Filter Mesh, where you can buy it, how it works efficiently in the function of equipment performance, typical uses in industry purchases, comparing other types of filtration to see what makes them different.

Sintered wire mesh is lamination of multiple layers of woven wire mesh which are sintered at the same time to make into a single ply, thus making its filtration precision double-sure than normal metal woven wire or pleated filter elements. Sintering makes pores stiff and uniform, which can realize more equally-filtering performance. The very high porosity of sintered wire mesh makes it also possible to achieve an excellent rate of flow, whilst efficiently retaining the particles. This makes it perfect for all the applications that require cutting-edge particle separation and evacuation. With our sintered wire mesh, it's possible to make product filtration more productive and pure.

If you need premium sintered wire mesh, then it makes sense to team up with a reliable and experienced manufacturer such as Xuancheng Filter Screen. With more than 15 years producing experience, we are now a leading manufacturer for various kinds of wire mesh for our professional technology and rich management experiences. Our ISO certification ensures that our products adhere to industry standards and are dependable for sensitive filter applications. When you select Xuancheng, expect the highest quality sintered wire mesh for your requirements of filtration.

The sintered wire mesh is commonly used as a filtration media but also can be added to other equipment for better performance. It is often used in the filtration of extruders, fluidised beds and various chemical processing systems. The sintered wire mesh is resistant to wearing and tearing prevent liquids from ruining the filtration process. You can have the benefits of increasing filtration efficiency, reducing downtime for cleaning and filtering, as well as upping productivity by utilizing sintered wire mesh in your equipment.

Sintered wire mesh is applied to numerous industries for it's extremely good filtration. In the chemical industry, it is utilized for catalyst reclaiming, polymer filtration and gas-liquid separation. In food and beverage industries, Sintered Wire Mesh is used for brewing filtration, food processing and pharmaceutical manufacturing! It is also used in the automotive industry for automotive paint filtration and engine construction. Due to its flexible structure, sintered woven wire mesh is highly demanded for critical filtration applications across all types of industries.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy