Ever wonder where our water or oil comes from? One way in which we accomplish this is by employing Dutch weave filter mesh. This mesh has small openings and is designed to trap dirt, etc. while allowing the water or oil to pass through it. Therefore, the question arises of what separates Dutch weave filter mesh from our usual filters found in homes or elsewhere?

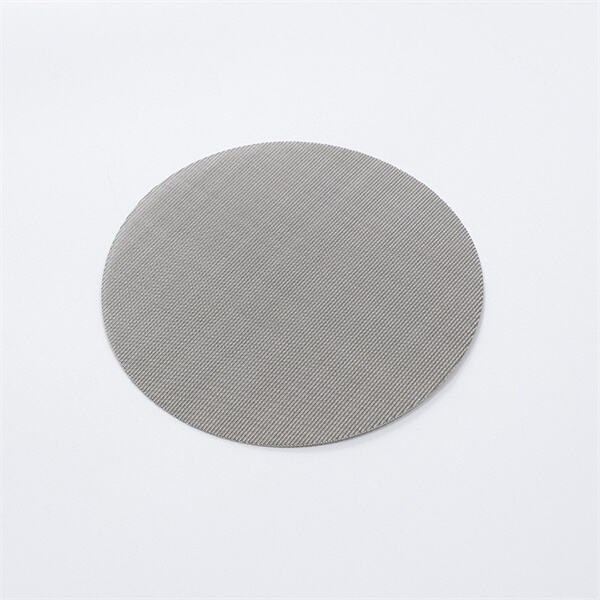

The two types of threads used to make Dutch weave filter mesh are the thick thread and the thin one. The thick thread is composite from side to back, while thin is up and down. This weaving pattern unique is to it creates small rectangles for airflow, and the holes are a lot smaller in diameter than what you see in any filter cloth. Heavy up is what makes the light down. This special weaving allows Dutch weave filter mesh to trap small particles that could get past the liquidity of regular filters, which is very important for quality control in most areas (clean water and oil).

Industries using Dutch weave filter mesh For instance, it cleans water, oil and even food items and beverages. Innocent question, why so many industries prefer to use this type of filter mesh? Dutch weave filter mesh is big strong, for one. General Purpose Silicone — This strain of silicone is great at high pressure and hot temperatures without breaking or tearing UIBar-gradepharmaceuticalapplicationspermits The oil sometimes can get really hot and will be at a high pressure, so this strength is pretty important as well..

Therefore, the Dutch weave filter mesh is especially useful for removing very small particles. This is called 1-micron filtration. Which is far smaller than a millimeter, it is measured in micron. A human hair is roughly 100 microns wide, for reference. What this means is that the Dutch Weave Filter Mesh can pick up things even 100 times smaller than a human hair in diameter of particle. Where even the teensiest bits can cause big problems, for use in industries such as this being able to filter out particles that small is important.

For example, in the semiconductor industry even minute particles can destroy their manufactured chips. Dust, and other fine particles are not tolerated during the process; if anything of this nature makes its way in, you will end up with a dud chip that isn't functional. Smaller particles are more likely to be missed, and a Dutch weave filter mesh can help in preventing such an occurrence. It is also amplified to be of great utility in the medicine industry because it traps bacteria and germs which can ruin medicines. Companies can make certain that their products are safe for human consumption by applying this filter.

There are some type of Dutch weave filter mesh that you need to get and put in it so make sure, whenever you want one for your particular work ask yourself a few important things? The first is what do you want to clean. Since materials contain various kinds of dirt or particles, you need to make sure what size the dirt or particle is and choose an accordingly filter mesh that can catch things smaller than it.

If you want to do a high cleaning and filtering work, Dutch weaving filter is the most appropriate mesh for maximum performance. Well-made mesh is manufactured using durable materials and proprietary weaving procedures. This means that the mesh is incredibly hard wearing and can effectively trap even virtually microscopic filths.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

The custom service consists of the selection of filter pore size as well as the material, shape, and other aspects and will provide customized filter products according to the diverse requirements of customers and the specific specifications of the extruder. Through customized services, the structure materials, filtration precision and other aspects of the filter can be improved in order to increase its filtration efficiency and service life. The production is based on the demands of the customer and waste is minimized to lower costs. Choose materials with the most suitable properties for the requirements and needs of the client and taking into consideration the requirements for corrosion resistance, heat resistance, wear resistance etc. Design a filter structure that is appropriate for the location and usage conditions of your customer.

The company has a knowledgeable after-sales service team, through telephone, online customer service along with social media and other ways of communication, it is able to quickly provide customers with technical support, product consulting and tracking cargo and troubleshooting, among other services. The company will contact customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the data. Furthermore, feedback is also fed back to product design and production departments to enhance the quality of products and services. The experienced team analyzes the root cause of the problem and provides basic solutions to minimize the chance of repeating the same problem. When the two are in harmony, will we be able to provide customers with an exceptional after-sales customer experience. This strengthens customer loyalty and promotes the long-term development of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy