Selecting the Right Mesh Density for Recycled PET Flakes In selecting an appropriate mesh density for your recycled PET flakes, you must ask yourself how it will affect the quality of your final product. Mesh density is the number of holes in a screen per linear inch; mesh size indicates projection openings that cannot be passed by particles. Knowing what difference metal mesh density makes in the quality of recycled PET flakes and things to look out for as a wholesaler will help you make the best choices for your process.

Effect of Mesh Density on Quality of Recycled PET Flakes

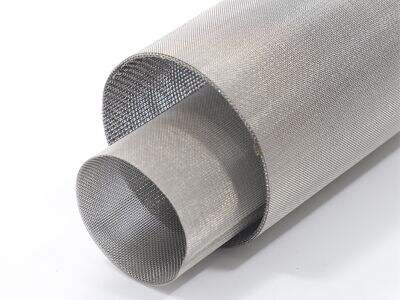

The quality of the recycled PET flakes greatly depend on mesh size that used in the recycling process. The higher mesh density, the smaller holes in the screen that separates and size-reduces the PET flakes. The latter can result in a relatively uniform product, particularly without contaminants or impurities. While in contrast, lower mesh density may allow bigger particles to pass, decrease purity level of the recycled PET flakes. In that sense, it is important to strike the right balance between steel wire mesh size and grain size so that the final product retains superior quality and efficiency as per your needs.

Wholesale Buyers Guide for Mesh Density of PET Flakes

As a wholesale purchaser, when you buy recycled PET flakes, it is essential to note that the mesh density utilized during recycling significantly influences your purchasing choice. Other applications may also have other mesh densities this line in order to reach the required quality and performance. If you require finely ground PETiс flakes (bottle-to-bottle), for high-end packaging material, then you can go with a higher mesh screen.

Find the Optimum Mesh Density of PET Flakes

Choose the right mesh density for your recycled pet flakes Having a reliable supplier that can supply you with high end products is significant. Xuancheng is a well-respected name in the field and with their high quality mesh densities for PET flakes. Xuancheng products are easy to find online and at industry trade shows and conventions. When you select Xuancheng as your mesh supplier, you know you have the best available ss wire mesh density for your PET flakes.

Optimal Mesh Density for PET Flake

The most ideal mesh density for PET flakes may differ according to the requirements in your recycling process. Xuancheng has various mesh density for choice to meet different demands. Generally speaking, the higher mesh count for a finer flake would be used and lower mesh count for a coarser. When selecting the right mesh density for your PET flakes, consider variables such as flake size, final product quality and recycling process efficiency. Xuanchengs experience staff is available to help you decide which screen mesh is most suitable for your particular application or industry.

What Need You Pay Attention to When Choosing Mesh Density for PET Flakes?

To determine the right screen size for your recycled PET flakes, you need to know exactly what your desired end-product will look like. A few questions to ask yourself include:

How big and good a video do you want at the end?

How efficient is the recycling process for varying numbers of mesh crossings?

How much will the mesh density affect the cost and effectiveness of recycling?

With these questions and teaming up with Xuancheng, you can decide what is the best mesh density for your PET flakes.