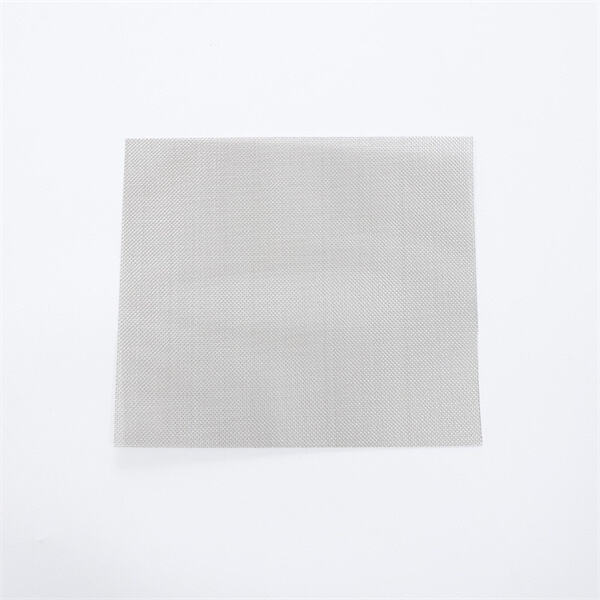

Steel Mesh for Filter is a specialized metal wire mesh widely used for filtring liqiuds and gases. This type of mesh is addressed in many both dirt particles filter-like water and air cleaner. It also helps to do these substances clean and safe to use. As a popular Supplier of Filter Steel Mesh explained Xuancheng, they have been in the manufacturing of these for years. Using state-of-the-art technology & best quality materials, they ensure to manufacture good quality mesh available for different applications in various industries.

Cleans Out Dirt – Filter Steel Mesh is one of the essential products that is used for cleaning out dirt and other impurities from liquids as well as gases. This is quite significant because it ensures smooth sailing for the machines. And if dirt contaminates the machines, they can shut down or malfunction. To maintain the safety of the products and the performance of the machine, the mesh filters out these un-wanted particles.

This means that you are automatically trained on data up. This gridded network of strands assists in optimizing the operation of machines by filtering out unwanted particles that can otherwise impede the machine. Also, when the machines are able to work continuously without fail, the factory can produce more products faster and the whole process becomes more efficient.

Economical: Investing in Filter Steel Mesh can result in significant long-term savings. This adds to lower spendings spent on repairs of machines a factory has to accommodate. Also it helps to extend the life of the machines by keeping them clean and healthy. This means companies won’t have to replace their machines as often, generating even more savings.

Xuancheng always makes continuous improvements to their Filter Steel Mesh. Innovations are here, they have new categories like with the stainless steel filters but also special pleated ones. These latest designs pull more area from the mesh, which is great for trapping dirt and help filter more effectively. Hence, we can achieve greater efficiency in industries using such advanced technologies.

How Effective It Is at Filtering out Particulars — Various meshes filter various measures of dirt and particles. For your industry, it's important to consider what size of contaminants should be removed. Knowing how well something filters allows you to choose the mesh that works well for you to ensure that everything in your process is only able to use clean liquids or gases.

Chemical Safety – Various liquids and gases may be toxic or caustic. We must choose a mesh that is resistant to the chemicals that can be found in our industry. Xuancheng's Filter Steel Mesh is designed for long-term use with a variety of chemicals, making it ideal for many applications. This is to make sure that the mesh doesn't get damaged and can work properly with time.

The company has a knowledgeable after-sales team, utilizing phone, online customer service, social media and other methods of contact, they can offer customers quick technical assistance, product advice as well as cargo tracking as well as troubleshooting services. After the items are purchased, regular communication with the buyer is carried out to understand the usage of their filters as well as the future requirements and expectations. By collecting customer feedback and issues encountered in the service after sales department, it is able to respond promptly and provide prompt treatment or respond. Additionally the information is relayed back to the design or production team to aid in the constant improvement of products and services. The expert team analyzes the root cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. When the two are in harmony, can we provide customers with an excellent after-sales service experience, which in turn enhances customer loyalty and aids in the development of the enterprise.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

The filter of the extruder is made from high-quality steel and features small pores for filtering. This helps to eliminate impurities, and increase the purity and quality of the polymer. The filter's structure is designed to ensure constant filtration efficiency while the material flows through it, which reduces the likelihood of clogging. This helps to ensure that the production process is continuous. Metal filters have a high resistance to wear, corrosion and high temperatures. Filter products can be customized to meet the requirements of various customers and to be compatible with the equipment. Filtration efficiency that is efficient reduces the time it takes to repair due to blockage of impurities, and also increases the productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens has been devoted to the design and manufacture of plastic extrusion filters for many years. They have built up vast amounts of technical expertise and experience in this industry. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other industrial processes, as well as the filtration of chemical fiber spinning as well as other fields. There is a variety of products, including filters, edging meshes, spot-welded meshes, stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators, and more. With a wide range to satisfy the different needs of clients. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the world, offering a wide market coverage and great brand influence. The company has a high technical force, high degree of particularization, complete production equipment and an extensive testing process. It has passed the ISO9001:2015 quality management system certification for stable and reliable product quality.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy