As far as other sorts of filtration are concerned, the filter band Xuancheng is a great solution for anyone seeking to separate liquids and similar substances. It has two states and intended to use in a lot of filtering tasks, therefore it is useful. Available in various sizes, this mesh can do both large and small jobs. Smaller mesh holes would allow your liquid nozzle strainer to catch small particle and other containment. That means that for all kinds of uses, you can rely on cleaner liquid and thereby have a safer family.

The current use is large-scale in all walks of life, filter metal mesh in many different industries have applications. It is most effective when used in the production of car parts, food processing, and pharmaceutical manufacturing. It is very convenient for many factories and businesses as it can adjust itself according to requirement.

Instead of that, it can be tailored to what you want. As there are many different sizes and shapes, it can be employed to a plethora of various jobs. This way you can always have the perfect mesh for your required filter no matter what the filter type is. Its flexibility is what allows this filter elements to have an invaluable use across a number of different industries.

This mesh, in particular, is one of the strongest and most durable, so it is a convenient variety for jobs that necessitate protection from fluids. As it has a long lifespan, you will not have to replace it frequently in the nearer future hence saving time and money. This strength can make it a excellent choice for numerous sorts of filtration in different applications.

If you are using the filter mesh at all times, this maintenance needs to be done even more frequently. Because clean filters are much more effective, it is important to look after the mesh. If you keep it clean then you can guarantee that it will still be able to do what its meant to when needed.

Xuancheng filter metal mesh is a wise and economical choice, especially for liquid filtration and much more. It is based in terms of being cost-effective compared to other filtering technologies too. They provide maximum capacity and loading capabilities while offering precise filtration and waste reduction, which helps in cutting processing costs.

It has a much longer life, so you can be sure that Xuancheng's filter metal mesh retains your valuable assets. You can be certain that it will last and deliver optimum performance for a long time, providing you with reliable filtration its whole duration. Having such a guarantee is essential as it produces reliable results and saves money for businesses that depend on good filtering.

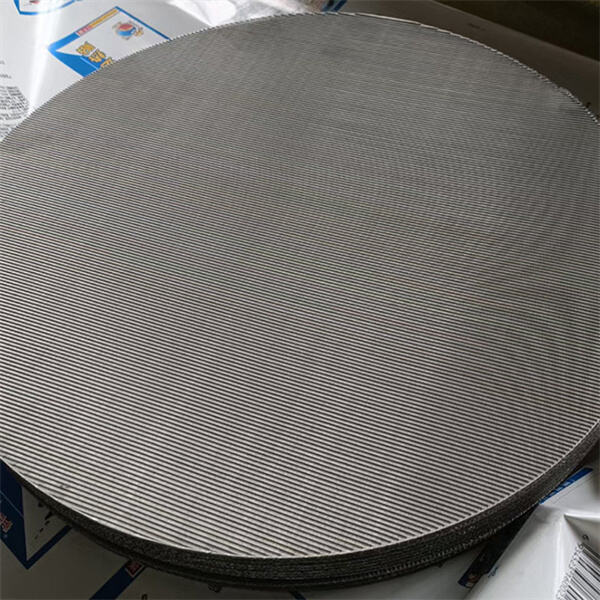

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens has been devoted to the design and manufacture of plastic extrusion filters for many years. They have built up vast amounts of technical expertise and experience in this industry. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other industrial processes, as well as the filtration of chemical fiber spinning as well as other fields. There is a variety of products, including filters, edging meshes, spot-welded meshes, stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators, and more. With a wide range to satisfy the different needs of clients. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the world, offering a wide market coverage and great brand influence. The company has a high technical force, high degree of particularization, complete production equipment and an extensive testing process. It has passed the ISO9001:2015 quality management system certification for stable and reliable product quality.

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

The company has a knowledgeable after-sales service team, through telephone, online customer service along with social media and other ways of communication, it is able to quickly provide customers with technical support, product consulting and tracking cargo and troubleshooting, among other services. The company will contact customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the data. Furthermore, feedback is also fed back to product design and production departments to enhance the quality of products and services. The experienced team analyzes the root cause of the problem and provides basic solutions to minimize the chance of repeating the same problem. When the two are in harmony, will we be able to provide customers with an exceptional after-sales customer experience. This strengthens customer loyalty and promotes the long-term development of the enterprise.

The customized service includes the selection of filter pore size along with the shape, material as well as other elements and is able to provide custom filter products according to the different needs of customers and the specific specifications of the extruder. With the help of customized services, structure as well as the material, filtration efficiency and other aspects of the filter are able to be improved, so as to improve the efficiency of filtration and extend its the life of the filter. The process is designed according to the actual needs of the client, thus avoiding the waste that is unnecessary, and aiming to save customers money. In accordance with the specific requirements and applications of customers, taking into consideration the specific demands such as corrosion resistance and high temperature resistance wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron and more. Based on the use of the customer's surroundings and conditions for installation make sure you design a functional filtering structure, like types of plates, wound types or cylindrical type, for example.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy